In an era where the global power equipment arena grows increasingly competitive, product quality and regulatory compliance stand as the twin pillars of market leadership.MELEC has long been at the vanguard of innovation in cable accessories, anchoring its prowess in a state-of-the-art, ISO 17025-accredited laboratory—engineered to deliver end-to-end solutions encompassing precision testing, R&D collaboration, and real-time quality assurance. Aligned rigorously with international benchmarks, the vast majority of its products have successfully cleared comprehensive form tests, substantiated by authoritative certification reports. At this very moment, the laboratory is orchestrating concurrent validation campaigns for three prestigious international clients hailing from Pakistan, Argentina, and Thailand—earning acclaim through unwavering technical excellence and service integrity.

Pakistan P**L: A Holistic Diagnostic Odyssey for 15kV Heat-Shrinkable Solutions

The Pakistani client's evaluation centers on a suite of high-performance components: 15kV three-core outdoor armored heat shrinkable termination accessory, indoor termination accessory, and15kV heat shrinkable straight joint. Guided primarily by IEC 60502-4, this exhaustive assessment serves as a gateway qualification for global deployment, scrutinizing every facet of performance and safety.

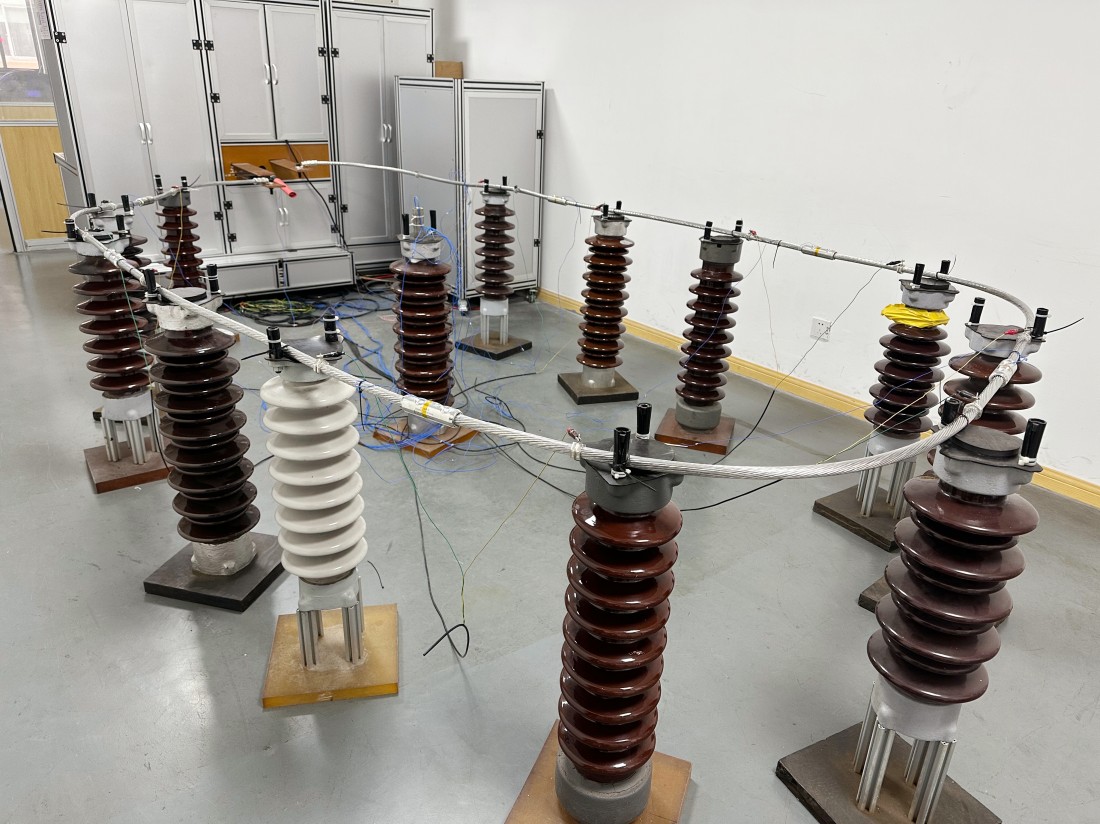

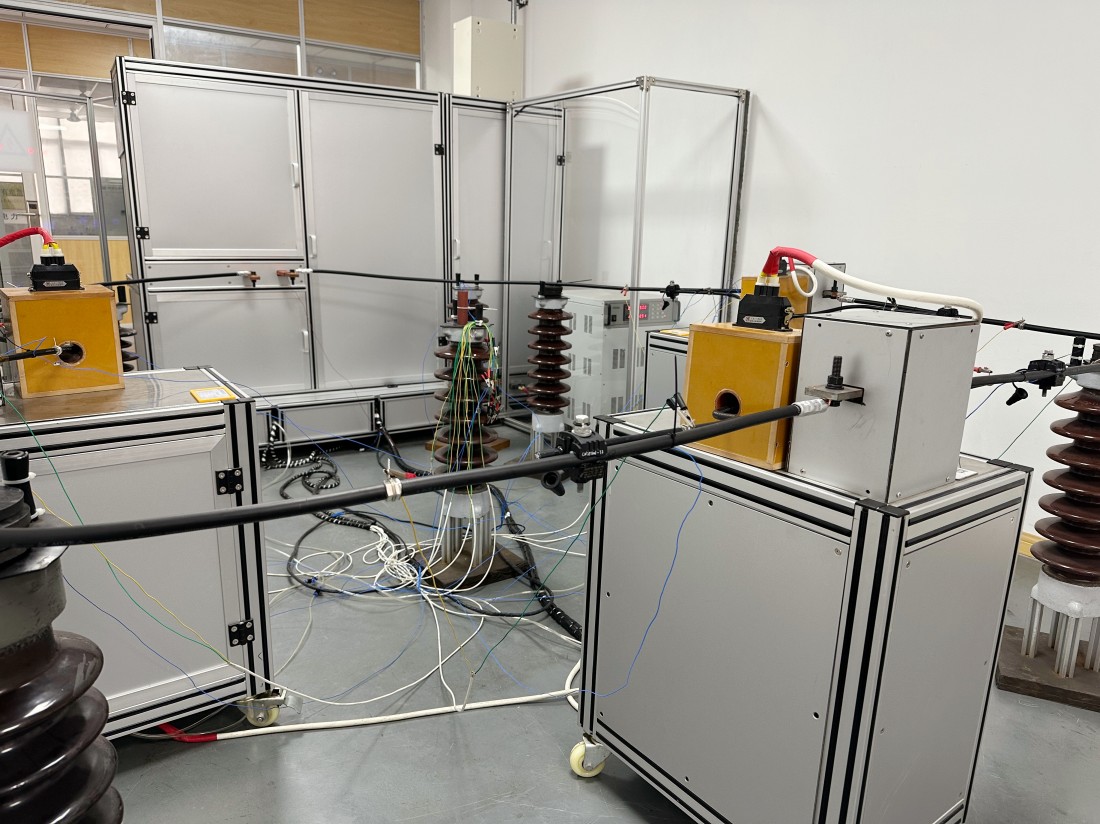

Employing a hybrid model of 'in-house expertise + third-party corroboration, MELEC ensures both agility and impartiality. The pivotal short-circuit test—a definitive measure of safety resilience—is entrusted to an independent accredited body, reinforcing credibility. Meanwhile,MELEC's own laboratory spearheads critical evaluations including high-voltage cycling, partial discharge analysis, rain exposure, underwater thermal cycling, salt fog resistance, and humidity endurance—each meticulously calibrated to simulate real-world operational extremes.

Launched on November 13th and scheduled for completion by January 12th of the following year, this two-month odyssey exemplifies precision engineering underpinned by systematic rigor.

Argentina C**T: Dual-Dimensional Validation of Mechanical Lugs and Connectors

For the Argentine customer'smechanical products—GLL70-240/4L and DTLL120-300-12/2L—MELEC has devised a bespoke testing regimen rooted in IEC 61238-1-3:2008, harmonizing mechanical robustness with electrical longevity.

Mechanical trials place paramount emphasis on tensile strength, subjecting theproducts to controlled stress loads that mirror installation forces and long-term operational strain—ensuring structural fidelity and fracture resistance. On the electrical front, aging behavior is probed via an integrated sequence of 'thermal cycling followed by short-circuit simulation,' replicating the punishing dynamics of extreme grid conditions. This dual-phase protocol validates the stability of insulation systems and the continuity of conductive pathways, delivering actionable insights for deployment across Argentina's demanding energy infrastructure.

Currently underway, this comprehensive campaign spans 100 to 120 days—an investment in reliability that echoesMELEC’s commitment to engineering excellence.

Thailand K**M: Multifaceted Aging Trials for Advanced Insulation Piercing Connectors

The Thai client’s product, designated JBC25-95/10-50/PG, interfaces with dual conductor configurations: 25–95/10–35 mm² and 25–95/25–50 mm². In response, the laboratory meticulously conducted evaluations in strict compliance with the EN50483-4:2009 standard, centering on two pivotal dimensions—electrical aging and climatic endurance. The testing regimen encompassed a comprehensive array of assessments, ranging from fundamental criteria such as visual inspection, dimensional accuracy, and material verification, to advanced performance evaluations including mechanical resilience, structural integrity, dielectric strength under wet conditions, low-temperature assembly functionality, resistance to corrosive atmospheres, prolonged climate exposure, and sustained current loading. Each test module mirrors a distinct phase in the product's life cycle—from factory birth to field deployment, from routine operation to survival in hostile environments—ensuring seamless adaptability across diverse wiring scenarios and environmental challenges.

With individual test durations ranging from 30 to 90 days, the entire program unfolds with military precision.

Laboratory technicians adhere to a strict daily regime of time-bound inspections and fix-point monitoring, scrupulously documenting every data point. Progress updates are relayed promptly to both the client and internal project teams, guaranteeing transparency, procedural fidelity, and data authenticity.

From the medium-voltage heat-shrinkable accessories in Pakistan to the ruggedizedmechanical products in Argentina and the intelligentinsulationpiercing connectors in Thailand,MELEC Laboratory remains steadfast in its mission: to uphold international standards as its compass, and technological mastery as its engine, delivering precise, dependable, and visionary testing services to partners worldwide. Moving forward,MELEC will continue to elevate its laboratory infrastructure and technical acumen, expanding its testing repertoire and accelerating innovation to meet the evolving demands of the global energy landscape.

34 clicks

34 clicks

+86-21-61656997

+86-21-61656997 info@melec.com.cn

info@melec.com.cn