In the field of cable accessories production, product quality is crucial to the stability and safety of power transmission. MELEC has been building the test center since 2005 and has continuously improved it. In 2016, it obtained the ISO17025 qualification. The R&D site has a building area of approximately 3,300 square meters, with a total investment of over ten million yuan. Integrating multiple functions such as testing and analysis, R&D support, and quality monitoring, acted as a key link in ensuring product quality.

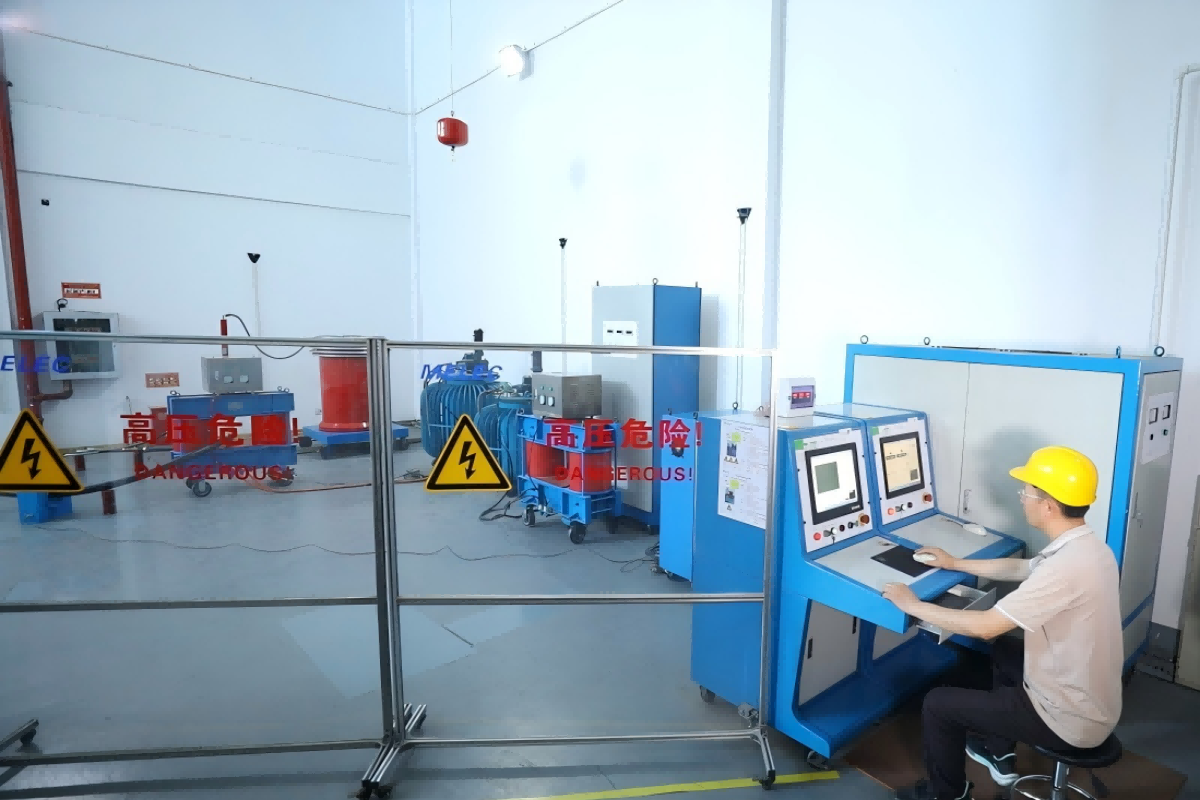

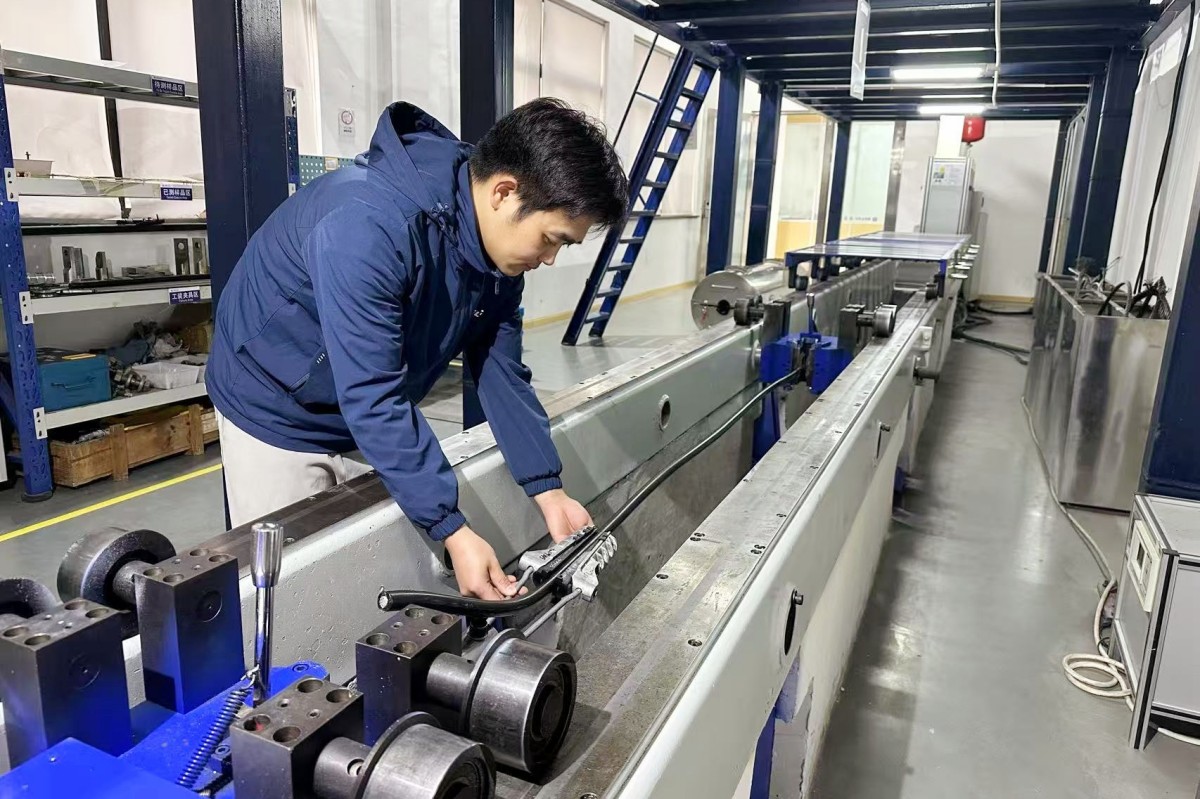

The test center boasts the capacity to conduct tests in the electrical and environmental fields, such as electrical ageing test, tensile test, swing test, underwater voltage withstand test, salt mist test, impulse voltage test, high voltage cycling test, etc., covering the electrical performance, mechanical properties, environmental adaptability and many other aspects of cable accessories.

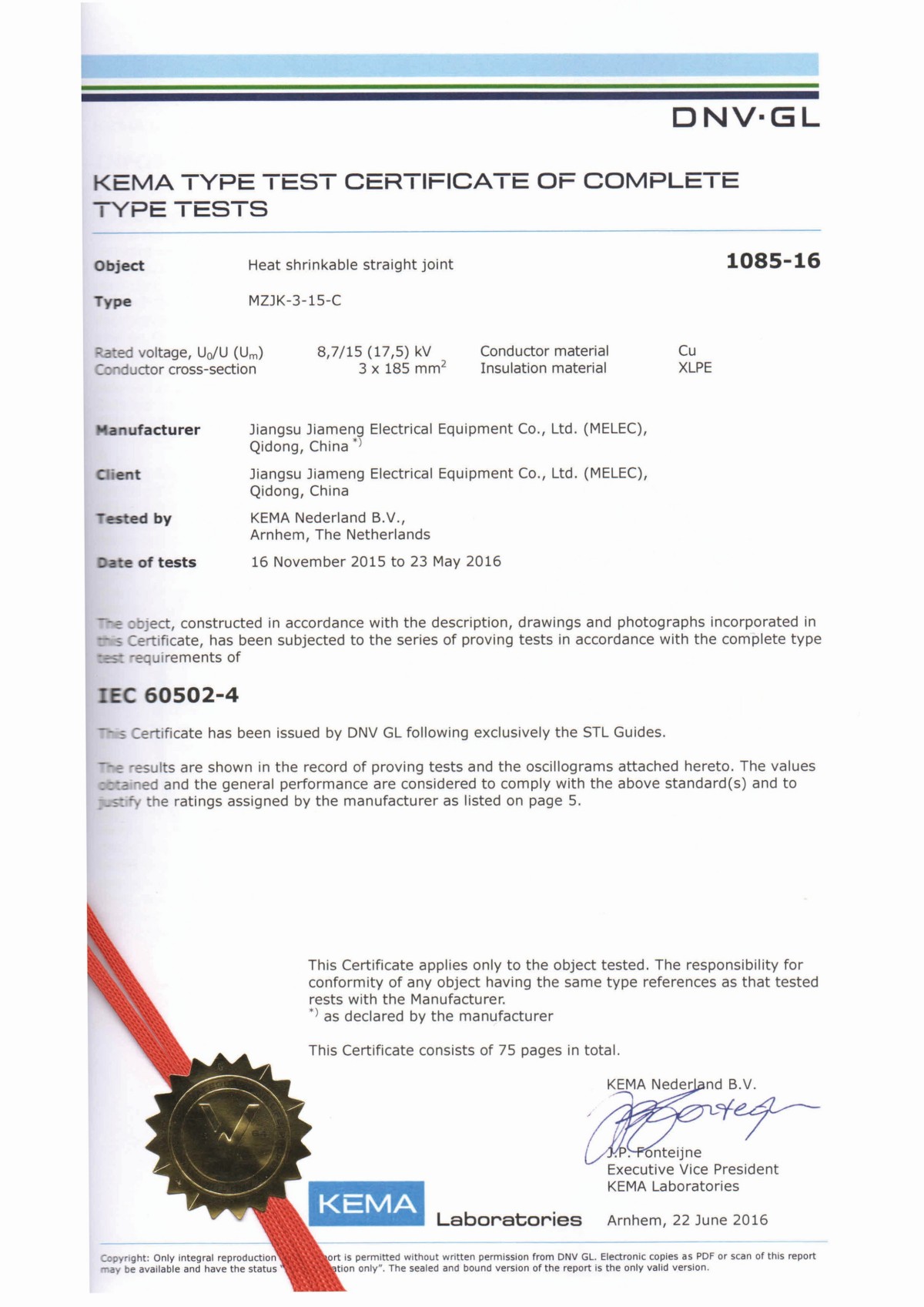

The test center is also furnished with a set of international first-class instruments and equipment, providing a solid guarantee for accurate testing, such as PBOREAS screw air compressor, shielded partial discharge laboratory, high-voltage tracking index tester, cantilever beam impact testing machine, etc. At the same time, the center is also equipped with tensile testing machine, hardness tester, densitometer and other equipment, ensuring the quality of raw materials from structural dimensions to material properties in an all-round way. According to statistics, the test center has a total of nearly 200 testing devices, and has obtained nearly 1,000 third-party type test reports, all from well-known foreign laboratories, including KEMA, SIRIM, ITEN, EPORT, COFRAC, ETS, etc.

The completion of the center is inseparable from a team with solid professional technical knowledge and rich inspection experience. The test center strictly follows international and domestic standards for testing, such as IEC, EN, NFC, GB and other recognized standards to ensure the accuracy and authority of the test results.

In practical applications, the test center provides strong support for the company's new product research and development. Through comprehensive performance testing of new products, problems in product design and process are found in advance, providing improvement directions for the R & D team, greatly shortening the development cycle of new products, and enhancing the market competitiveness of products. In terms of product quality control, regular sampling of cable accessories on the production line is carried out to discover and solve quality problems in the production process in time to ensure that every product leaving the factory meets high-quality standards.

In the future, the test center will continue to increase investment in equipment renewal, technology research and development, and talent cultivation. It will keep introducing more advanced testing equipment and technologies, expand the scope of testing projects and services, and provide better testing services for the development of cable accessories industry. Meanwhile, it will strengthen cooperation and exchanges with domestic and foreign scientific research institutions and industry associations to jointly promote the technological progress and quality improvement in the cable accessories industry.

174 clicks

174 clicks

+86-21-61656997

+86-21-61656997 info@melec.com.cn

info@melec.com.cn